Our Heat Treatment - Your Solution

Schulz in Krefeld can provide you with heat treatment solutions in all the relevant dimensions. Whether it’s steel-framed structures, machinery, pipes, steel sections or steel slabs – we can provide advice and suitable solutions on anything that may require heat treatment.

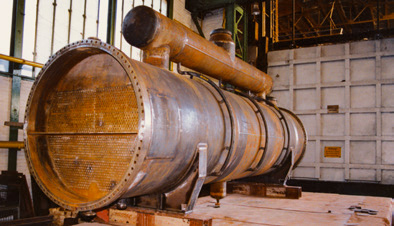

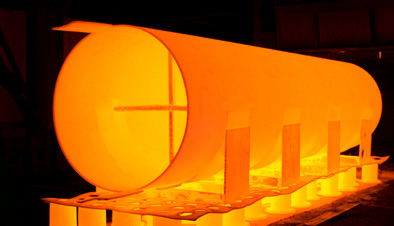

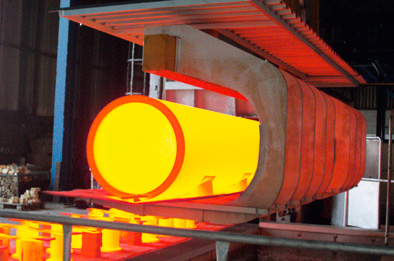

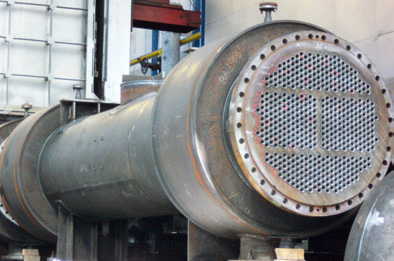

We specialise, in particular, in two areas: “Heat Exchangers” and “Large Vessels and Machinery”. These are particularly difficult to anneal and to shrink-fit rollers, gears, cylinders and pistons.

Heat Treatment Processes

Materials

All ferrous and non-ferrous metals such as general structural, tempered and case-hardened steel, corrosion- and acid-resistant stainless steel, special high-alloy materials, non-ferrous metals, light metals and casting materials, e.g. spheroidal graphite iron.

Do you need a material analysis or an identification of values? If you require such services we would be pleased to put you in touch with independent test labs.

Our Experience - Your Benefit

Backed up by several decades of experience, our company has been in the German town of Krefeld since mid-1970, covering over 13,000 square metres of floor space. We specialise in a wide variety of heat treatments, different materials, components and dimensions. We use eight stationary inductive heat treatment systems, fired by gas burners and controlled electronically.

Our furnaces and heat treatment equipment are subject to regular monitoring by TÜV Rheinland (the Technical Inspection Authority for the Rhineland) under the EN 60584-1 standard.

The requirement profile includes

We also have the usual quality assurance system in compliance with ISO 9001:2008.

Based on state-of-the-art technology, all heat treatment is conducted and documented by us professionally and 24/7. Orders are processed by a skilled workforce, covering all sectors of the metalworking industry.

We have in-depth knowledge of all heat treatment processes and the flexibility of a mediumsized enterprise.

These are good reasons to trust us with the heat

treatment of your products.

Our Experience – Your Service

Our company provides heat treatment facilities with the following properties:

Temperatures:

Monitored and controlled from room temperature to 1,250°C

Maximum dimensions of furnaces:

19 m long, 6 m wide, 5 m high

Maximum loading capacity of furnaces:

350 metric tonnes

Crane capacity:

100 metric tonnes

Water quenching basin:

8,000 x 3,000 x 3,600 with immersion capacity up to 12 metric tonnes, integrated circulating system, recording of water temperature and charging time less than one minute.

Air annealing with the use of a blower:

To ensure uniform heating during heat treatment, hot air from the furnace is fed, for instance, through the tube bundle of a heat exchanger.

Our Dimensions – Your Choice

Furnace 510

Bogie hearth furnace, 20 burners, 100 kW

- 5,500 x 3,800 x 3,600 mm (LxWxH)

- Temperature up to 1,100°C

- 2 bogies, 80,000 kg, each with 80,000 kg load-bearing capacity

Furnace 540

Bogie hearth furnace, 40 burners, 120 kW

- 19,000 x 5,000 x 5,000mm (LxWxH)

- Temperature up to 750°C

- 1 bogie, 200,000 kg load-bearing capacity

Furnace 550

Bogie hearth furnace, 30 burners, 120 kW

- 12,000 x 4,300 x 2,500 mm (LxWxH)

- Temperature up to 1,100°C

- 1 bogie, 60,000 kg load-bearing capacity

Furnace 570

Bogie hearth furnace, 12 burners, 230 kW

- 7,000 x 2,000 x 1,850 mm (LxWxH)

- Temperature up to 1,250°C

- 2 bogies, 30,000 kg, each with 80,000 kg load-bearing capacity 2 water basins with charging points

- 8,000 x 3,000 x 3,600 mm (LxWxH)

- Continuous circulation of water Immersion device up for up to 12,000 kg

Furnace 580

Bell furnace, 3 burners, 150 kW

- 1,450 x 1,450 x 1,200 mm (LxWxH)

- Temperature up to 1,100°C

- Loading capacity up to 1,000 kg

Furnace 590

Bell furnace: 2 annealing stations, 10 burners, 350 kW

- 6,300 x 4,350 x 4,000 mm (LxWxH)

- Temperature up to 1,100°C

- Loading capacity up to 150,000 kg

Furnace 600 (lab furnace)

Electrically heated chamber furnace

- 600 x 400 x 300 mm (LxWxH)

- Temperature up to 1,000°C

Furnace 610

Shuttle furnace, 20 burners, 300 kW, 2 annealing stations

- 16,900 x 6,000 x 5,500 mm (LxWxH)

- Temperature up to 700°C

- Loading capacity up to 300,000 kg per loading point

Crane capacities:

- 100,000 kg, 50,000 kg, 40,000 kg, 32,000 kg

Contact

Wilh. Schulz GmbH

Spezialglühbetrieb

Hülser Straße 764 a

D-47803 Krefeld

Contact

Tel +49 (0) 2151 899940

Fax +49 (0) 2151 758707

anfragen-glueherei@wschulz.com

inquiry-heattreatment@wschulz.com

GPS

51°21'31.4"N 6°31'25.9"E

Terms and Conditions

Our "Terms and Conditions for Contract Work" are available in PDF format.